Moisture: A Silent Saboteur in Metal AM!

😈 Moisture: A Silent Saboteur in Metal AM! #MaterialsMonday

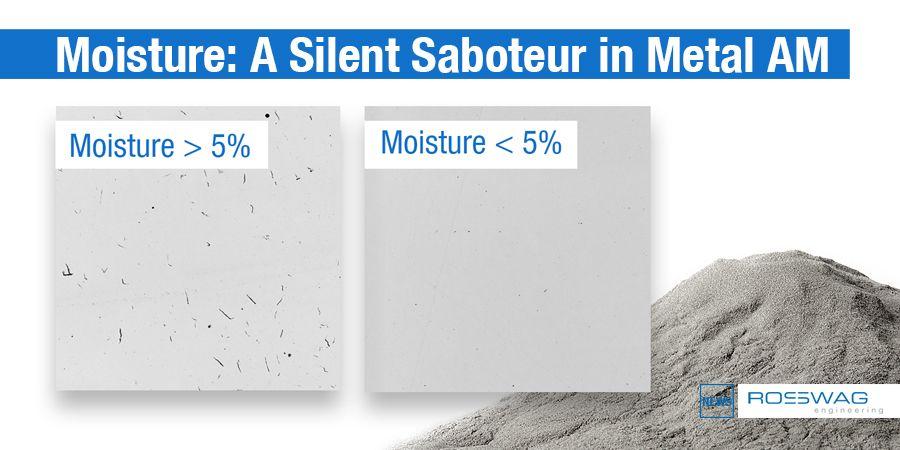

In the intricate world of Laser Powder Bed Fusion (LPBF), even a low percentage of moisture can be a foe to tool steels. Why? Moisture, often overlooked, can lead to the formation of cracks during the LPBF process, compromising the integrity and performance of the final product. It's a subtle yet significant challenge that can undermine the efforts to achieve high-quality tool steels. Understanding and controlling this factor is crucial for ensuring the robustness and reliability of parts.

At Rosswag Engineering we have implemented various strategies to monitor and, if necessary, reduce the moisture content of the powder:

👉 Measurement of moisture content and flowability of all powder batches and optional repackaging

👉 In-house developed moisture monitoring in the main tank of our SLM280 from SLM Solutions

👉 Standardized usage of the vacuum drying module from AMProved for fast and efficient drying of metal powders

Let's focus on meticulous moisture control in LPBF! By doing so, we not only enhance the quality of tool steels but also unlock the full potential of additive manufacturing. Share your thoughts and experiences on this often-overlooked aspect of metal AM. What are you doing to control and reduce moisture?